Downloads

- TRASCO® couplings (1,5Mb)

- ATEX Annex (1,4Mb)

- ATEX Use and Maintenance Manual (3,5Mb)

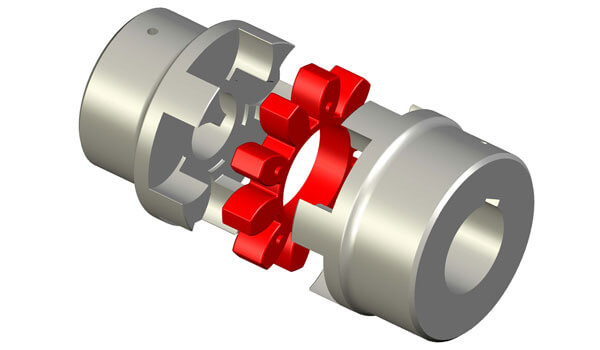

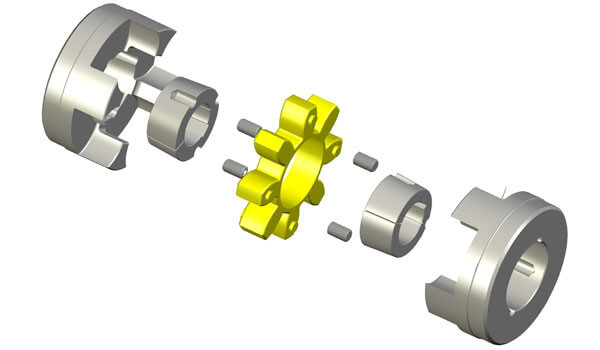

TRASCO® coupling is the flexible and omocinetic coupling that assures the best performance in relation to the physical space occupied in its class. It has a very compact design and allows safe power transmission by absorbing peak loads and torsional vibrations. Moreover, the elastic design of the polyurethane gear ring compensates for angular and radial misalignments and also absorbs small shaft length variation.

TRASCO® couplings are dimensionally manufactured to hub types “A” and “B”, the difference being the maximum shaft diameter which hubs can accept (corresponding respectively to the first and second code number). Long hub execution “L” (allows full coverage of the motor shaft) is available in both “A” and “B” executions.

TRASCO® couplings type GRB for taper bushing SER-SIT®, are manufactured in cast iron GG25.

They combine the typical high performances of standard TRASCO® couplings with the advantages of easy mounting and dismounting offered by the taper bushing SER-SIT®.

These hubs are manufactured in two different mounting executions:

The GRB execution eliminates the problem of fitting corrosion, making it suitable for all type of machinery.

Hubs type B1 may be axially moved for spider replacement.

This execution has been introduced to incorporate advantages offered by the SIT-LOCK® CAL 8 locking elements in the shaft-hub connection. The system allows for a quick, safe and backlash free mounting without the use of keyway and eliminating need for lock washers, spacers and stop rings. Many different solutions may be created to solve all kinds of application needs. Included below is a useful example. In fact, the same hub bore allows for the fitting of different shaft diameters.

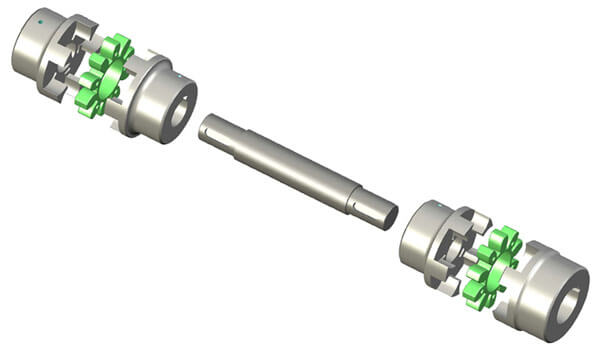

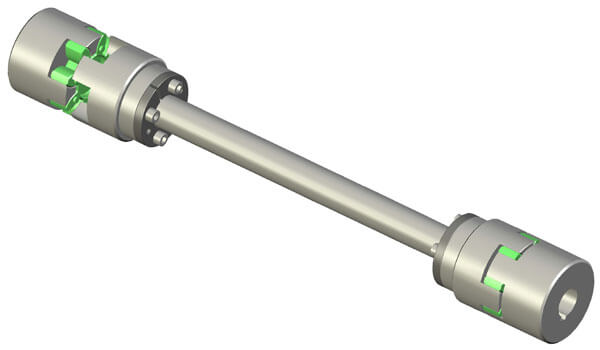

The GRL series allows the joining of two shafts (even very distant) through two TRASCO® couplings and an intermediate shaft (length “Lw”) of customized dimension. The presence of two polyurethane rings permits high dampening capability and greater radial misalignments. As a standard, hubs are made of cast iron, while shafts are made from steel; though, different materials can be used depending on the application.

The GRL CAL3 series allows the joining of two shafts (even two spaced) through two TRASCO® couplings and an intermediate shaft (length “LR2”) of customized dimension, mounted with shrink discs on the hubs.

The presence of two polyurethane elements allows high dampening capability and greater radial misalignments.

As a standard, hubs are made of cast iron, while shafts are made of steel; though different materials can be used according to different applications.

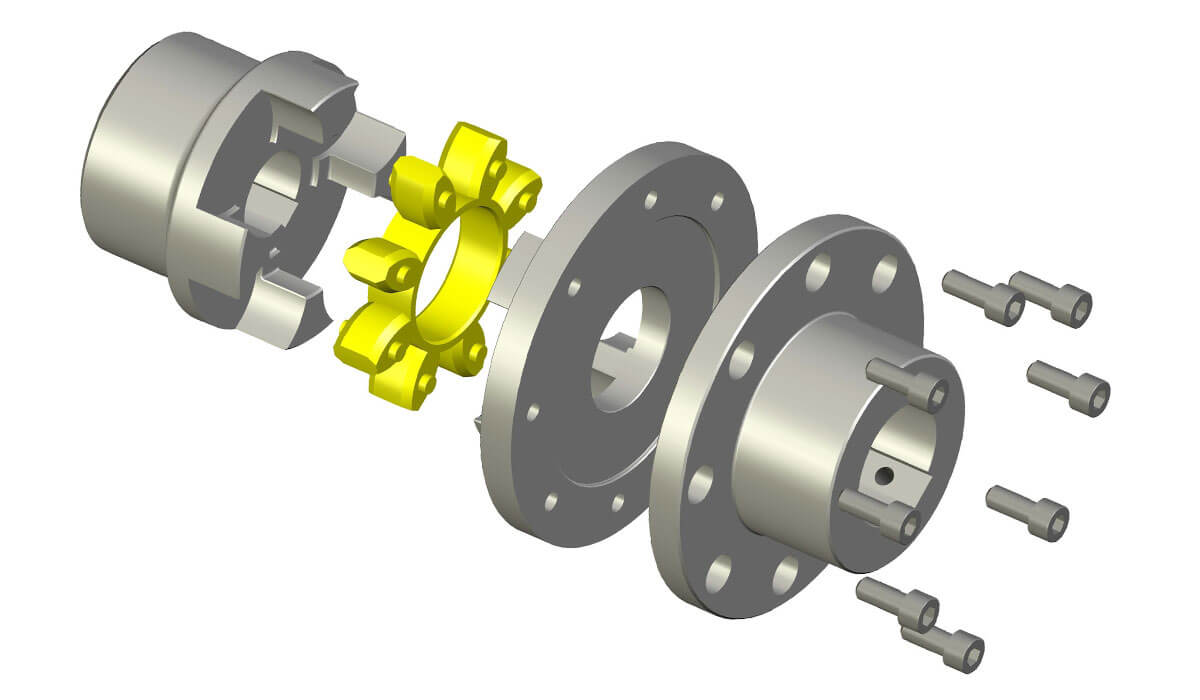

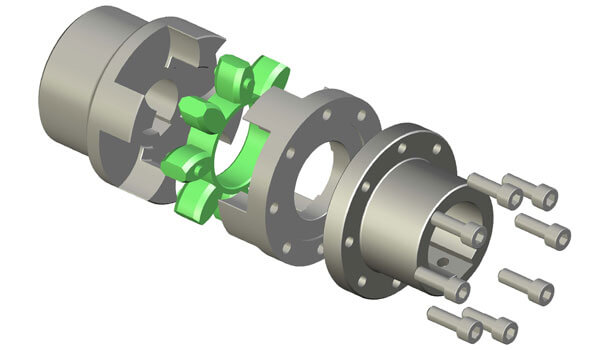

The GRF series with flanges has been developed for applications on heavy machinery and to combine different shafts and flange solutions.

The GRF C series has the same characteristics as the GRF series, while being compact in dimension.

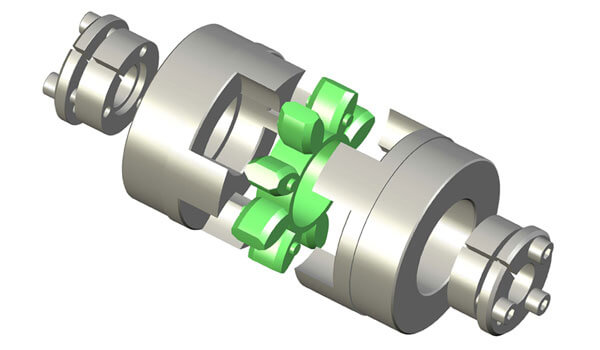

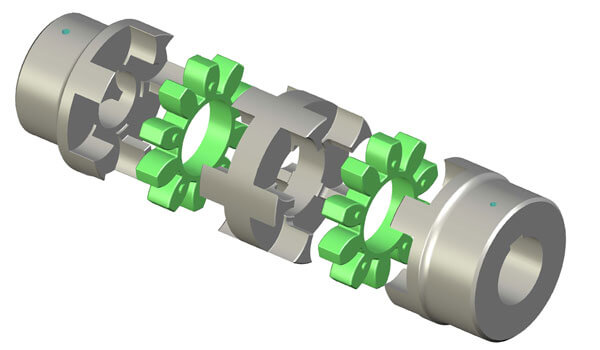

The GRS series allows compensation of high axial, radial and angular misalignment. Additionally, the use of the double spider allows for twice the torsion angle and provides very high dampening effect.

The GR FRT series has been developed to suit drum brake (FRT) transmission.

It is considered an elastic coupling consisting of:

Also, assembling of different dimensioned brake drum to any kind of coupling is allowed.

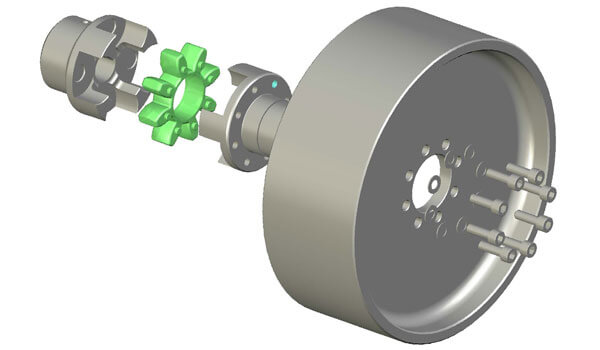

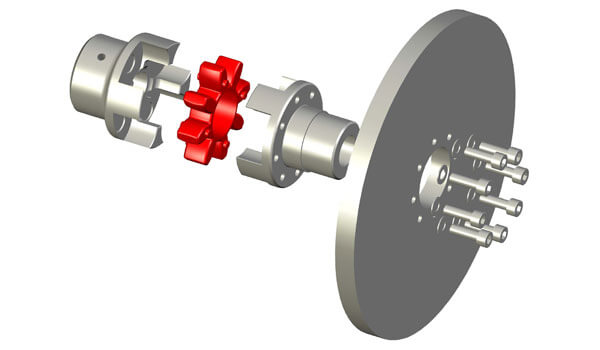

The GR FRD series has been developed to suit disc-brake (FRD) transmissions.

It is considered an elastic coupling consisting of:

Also, assembling of different dimensioned brake discs to any kind of coupling is allowed.